Behind the scenes at ifolor: How AI image enhancement powers exceptional photo prints

ifolor doesn’t need much of an introduction. If you’ve ever ordered a photobook or a stack of 10x15 prints from Switzerland, Germany, or Finland, there’s a good chance they passed through ifolor’s production line. We recently visited their headquarters in Kreuzlingen, Switzerland, just a few steps from the German border, to see how a century-old photo lab evolved into a modern, on-demand photo printing powerhouse.

A legacy of quality, evolved through innovation

Founded in 1961 as Photocolor Kreuzlingen AG, ifolor has grown from a family-owned Swiss mail order photo lab into one of Europe’s most trusted names in personalized print. With millions of orders shipping each year, their production facility balances scale with remarkable consistency.

What sets them apart isn’t just scale — it’s a lasting commitment to quality. From the rapid spread of ‘photos by post’, where customers could send in their films using the famous Photocolor bag and receive their 36 or more prints by post within a few days to today’s Photo Book Premium Photo Paper, personalized photo gifts and Wall decorations, ifolor has spent decades refining the tactile language of memory.

Why image enhancement matters

In the world of digital photo printing, input quality varies dramatically. Customers upload images from smartphones, old digital cameras, and social media — with resolutions often well below industry standards.

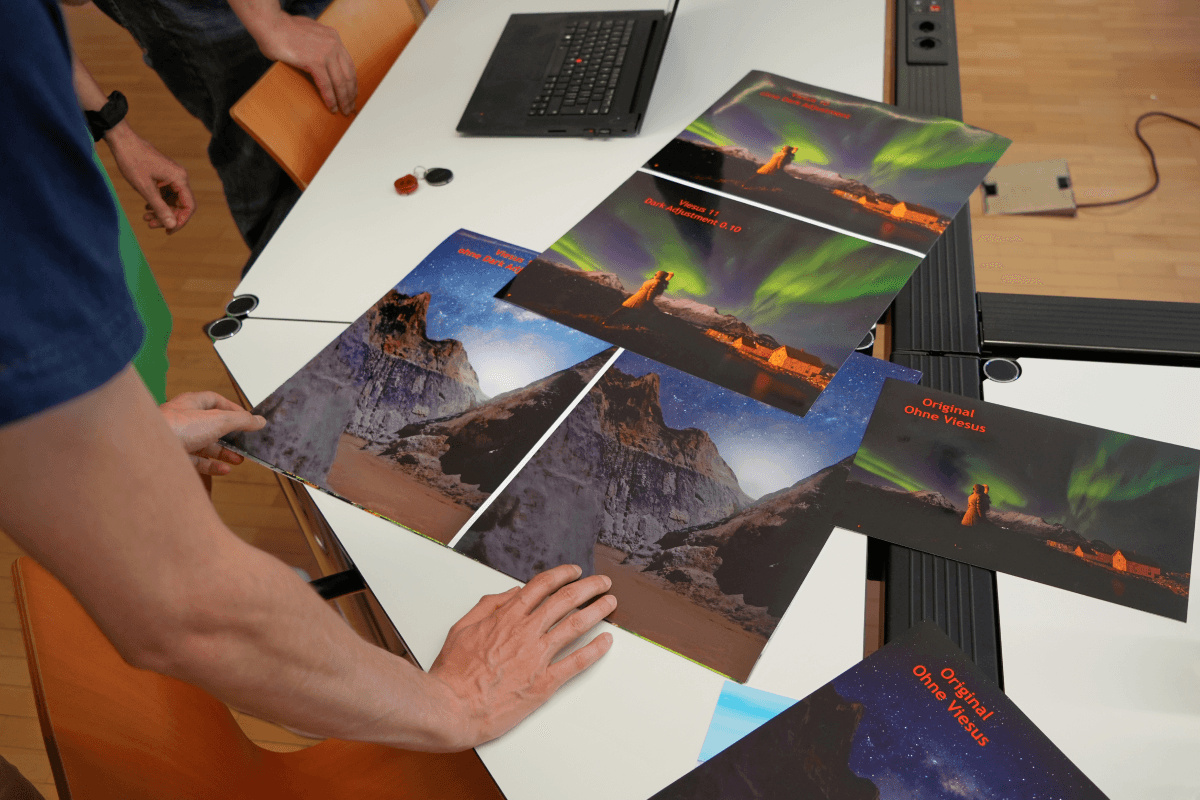

Most professional printers recommend 300 DPI for crisp output, yet many online submissions come in under 150 DPI. Low-res uploads result in pixelated or blurry prints, frustrating both providers and customers. That’s where AI photo upscaling from Viesus comes in — turning low-quality inputs into sharp, print-ready assets.

From manual fixes to fully automated workflows

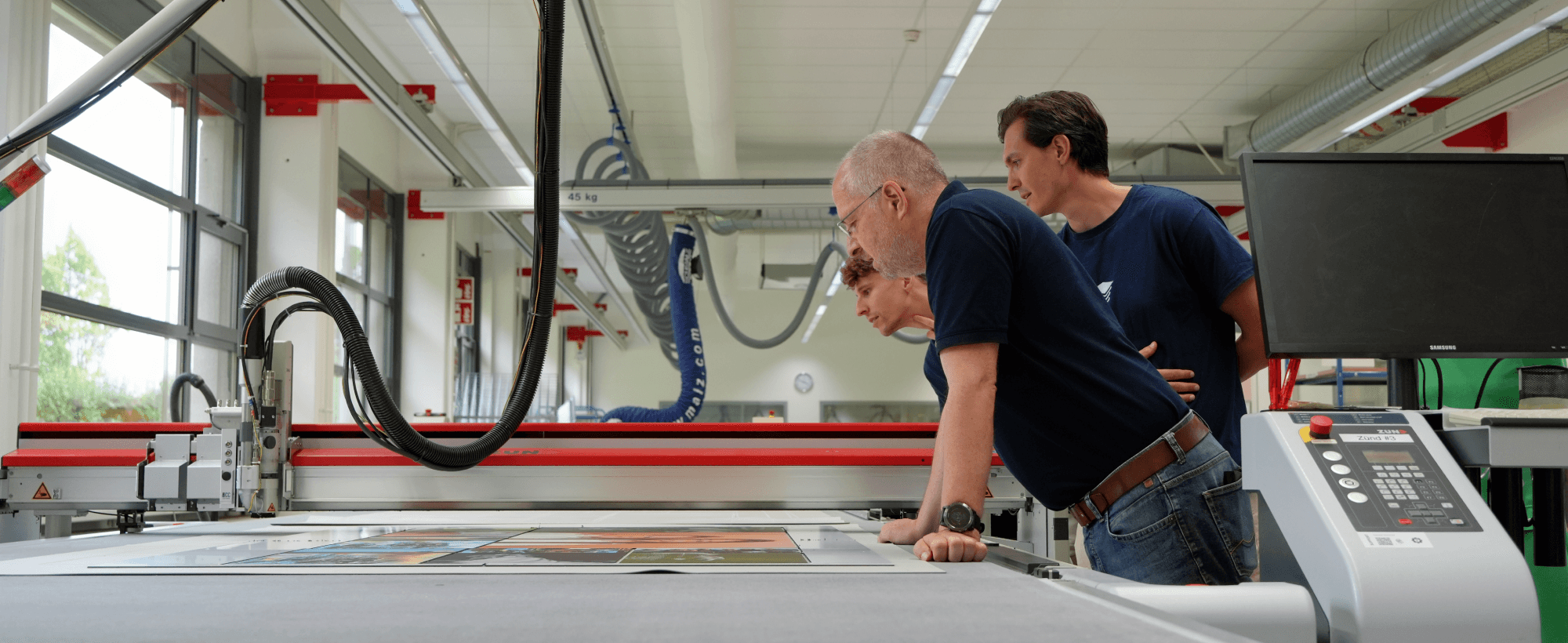

Viesus began as a desktop tool for scanning and correcting analog images. Today, it runs fully automated on ifolor’s in-house servers, embedded directly into their production process. Today, nearly 99% of all printed images go through automated image correction using Viesus — ensuring consistent quality without the need for manual retouching.

Each file is analyzed, scaled if needed, and optimized — adjusting sharpness, contrast, and color accuracy while preserving natural skin tones and avoiding the over-processing common in some AI tools.

As ifolor’s Head of Quality Management Systems, Andreas Schmidt, put it: “Customers should never be concerned about image quality. They just need to know they’ll get the best.”

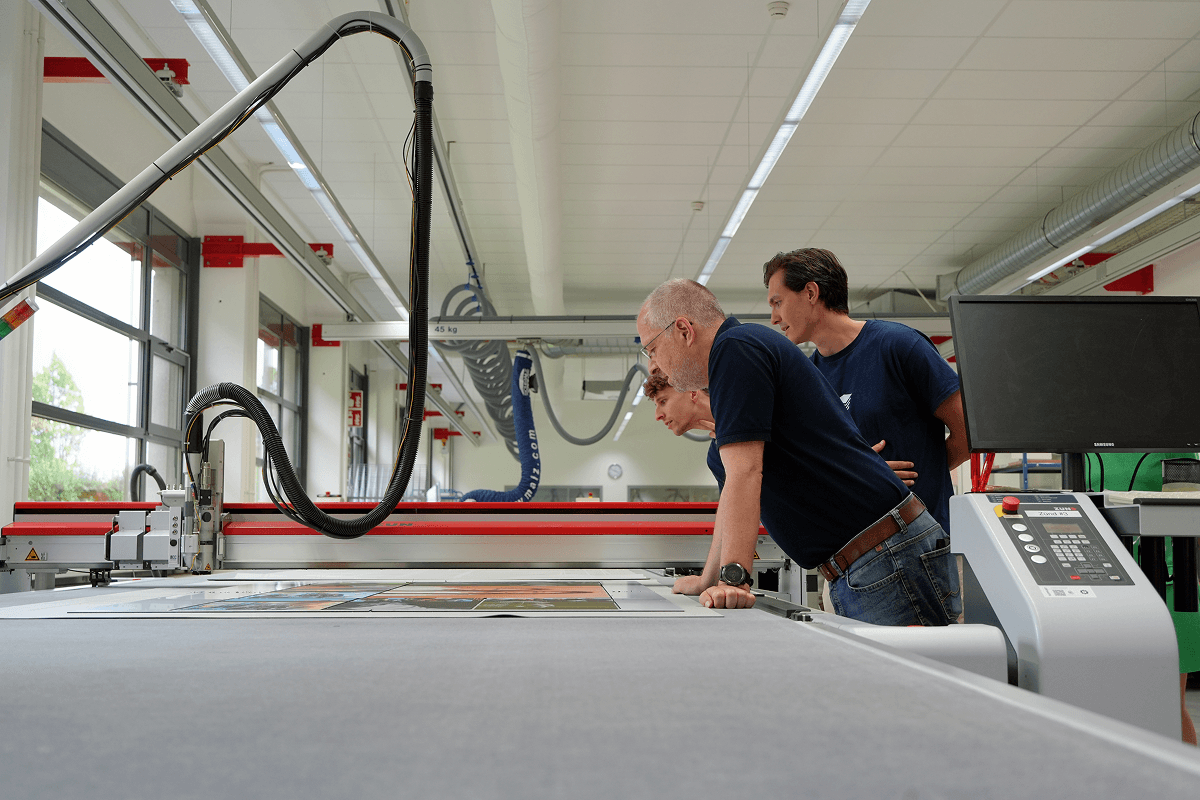

Hands-on quality check with ifolor team

Automation at scale: Inside the ifolor workflow

During our visit, we saw how this invisible technology quietly optimizes the print-on-demand workflow — powering a highly efficient operation:

- Customer uploads — primarily over weekends

- Image enhancement — automatic optimization via Viesus

- Photo printing — using silver halide, inkjet, xerographic or hybrid substrates

- Product assembly — including cutting, binding, and quality checks

- Delivery — scalable logistics with up to 3 or 4 shifts during peak season

Just to give an example: ifolor produces thousands of personalized photo products every day, and thanks to Viesus, what used to take a prepress operator 3–5 minutes per image now happens in seconds, hands-free.

The power of invisible technology

Customers don’t interact directly with Viesus — but they benefit from it with every order. Whether it’s a vacation photo, family portrait, or wedding shot, they can trust the result will be print-ready, vibrant, and sharp. This helps preserve life’s most beautiful moments and brings joy when looking at printed, tactile products.

This invisible reliability enables ifolor to uphold strong delivery guarantees — even during Black Friday and holiday peaks — without compromising quality.

Experience the difference

As ifolor continues to scale and innovate, Viesus is proud to support them with technology that enhances quality invisibly — but measurably.

If you haven’t yet explored ifolor’s products, now’s the time. From Photo Books to Wall decorations, every piece reflects a legacy of quality — powered by intelligent automation.

Visit ifolor.com to see the product range or learn more about how Viesus can elevate your print workflow at viesus.com.